LC1 Hotfire

The Project

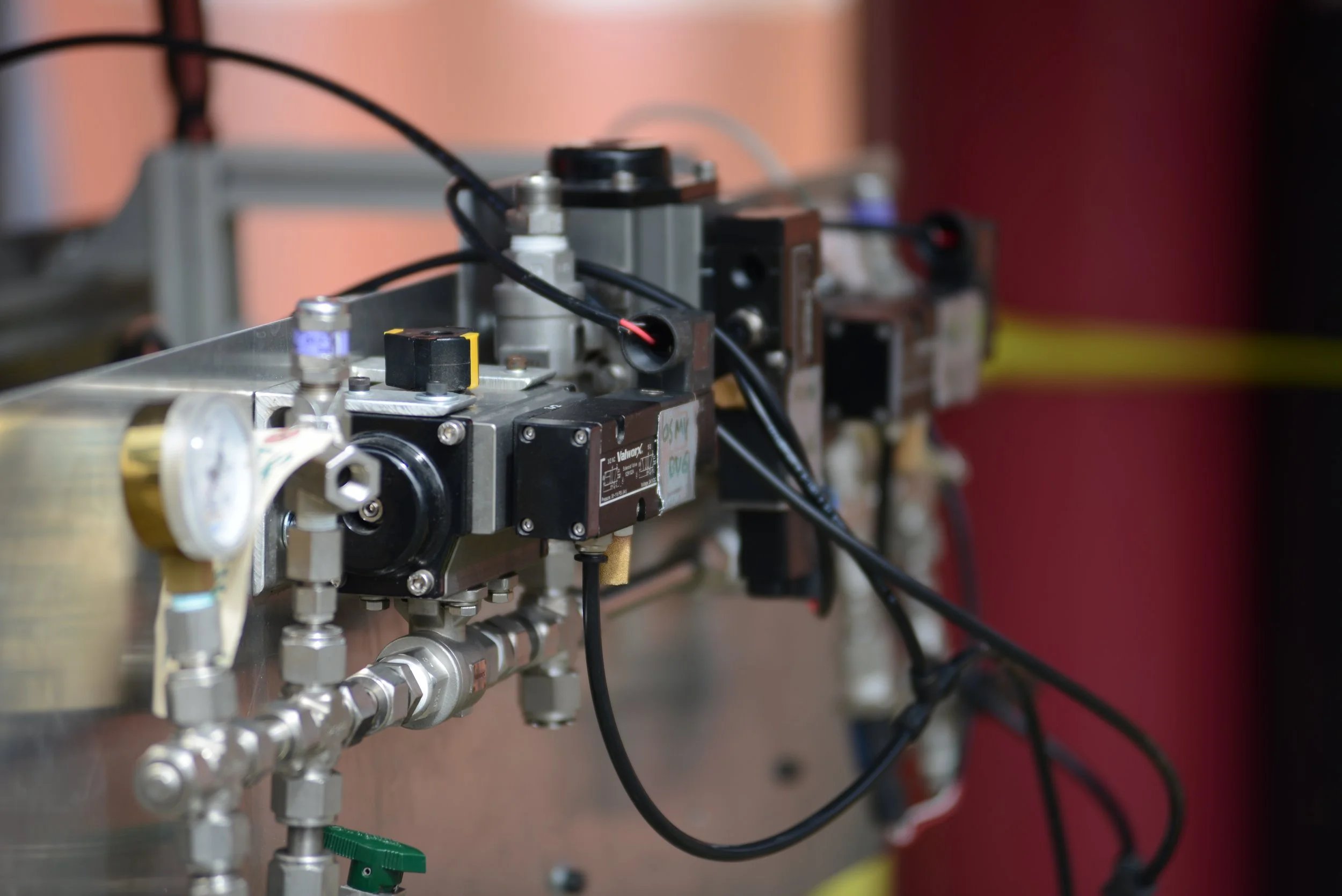

Liquid Courage I (LC1) was SARP's first ever liquid bipropellant engine. It was an ablatively cooled engine that ran 75% ethanol for fuel and nitrous oxide for oxidizer, along with helium as a pressurant. The engine had a pintle injector with two coaxial phenolic resin sleeves and a graphite nozzle. The team successfully fired the engine for the first time in May 2024, validating our student designed and manufactured test stand, fill system, and avionics infrastructure, although the engine itself did not perform nominally.

My Contribution

I was a fluid systems engineer leading up to the static fire and I had just been selected to be the next Project Manager, so I was juggling two roles. I was a part of the Hazard and Operability study to verify the safety of our system and implement changes on the nominal states of valves. In preparation for the fire, I helped clean our lines, especially the ones that had to safe for flowing nitrous. I also got to assemble the fill stand and check for leaks at low and high pressure. Our avionics team needed a lot of support with the wire harnessing, so I got to solder many of the connectors that retrieved data from the pressure and temperature sensors on the test stand. As the Project Manager in training, I tracked our progress with thorough checklists, recording anomalies and making the critical go/no-go call for fire. Lastly, I helped set up the high speed camera and operated it during the fire, capturing 1,000 fps footage of the test.

What I Learned

I learned a lot about how liquid rockets work through my contributions to this project. When I started out on the fluids team, I had no idea what a P&ID was or even how the engine worked and by the time the year was over, I was able to contribute to making sure our system was safe and successful. My gains in technical knowledge prepared me to take over the entire team and unlocked a passion for liquid engines that has continued to grow since then. Seeing the engine fire was an incredible moment that I'll never forget, and truly showed me how rewarding it can be to work towards a common goal with other engineers.

Closeup of the ox side of our fill stand

The team after our static fire

The engine's nozzle, which blew out after we hard-started